John Lee was exhausted. Burnt out from working 70-hour weeks for more than a year. Tired of not being able to climb in the company for which he had given seven years.

He laughed. “You can ask my wife,” he said about working a schedule of 13 days on, one day off.

“I wanted something new,” Lee said. “I just didn’t know where to go.”

An ad he saw on a social media feed pointed him in the right direction. It also changed his life. It was touting a new maintenance technician training program that was being offered at no cost at SUNY Jamestown Community College.

Engineering Services in Olean, N.Y. after completing the short-term machining/CNC

operator training program at JCC.

“I didn’t really think anything of it,” Lee remembered. “I clicked ‘send me more information’ and they reached out to me, telling me about the maintenance tech program, how it was free and how you can get this great education. It really led me to where I am now.”

As Lee explains it, his online resumes on LinkedIn and Indeed have been “blowing up” lately. He usually is contacted by four or five manufacturing companies a day – many in the Buffalo, N.Y. area – who need trained maintenance technicians.

Wanting to stay closer to home, the Sinclairville, N.Y. resident and soon-to-be first-time father recently accepted a maintenance technician/electrician position with Nestle Purina in Dunkirk, N.Y. The new job provides Lee nearly a $10 hourly raise.

Lee and eight others completed the 10-week, 292-hour maintenance technician program at JCC’s Jamestown Campus in December. Meanwhile, five students finished a similar short-term machining/CNC operator program at the college’s Cattaraugus County Campus in Olean, N.Y.

Classes for a new cohort are set to start in February, JCC Workforce Development representatives shared, with additional opportunities available beginning in the summer.

Lee has become one of the greatest advocates for JCC’s classroom learning and hands-on training that prepares students for entry-level manufacturing jobs that are in demand and pay well.

“With this program, I have been the happiest,” he said. “I have felt the happiest and most optimistic I’ve felt in literally years. It’s a weight off your shoulders. It’s scary to leave your job and career of seven-some years, but I’m not worried. I feel so confident.”

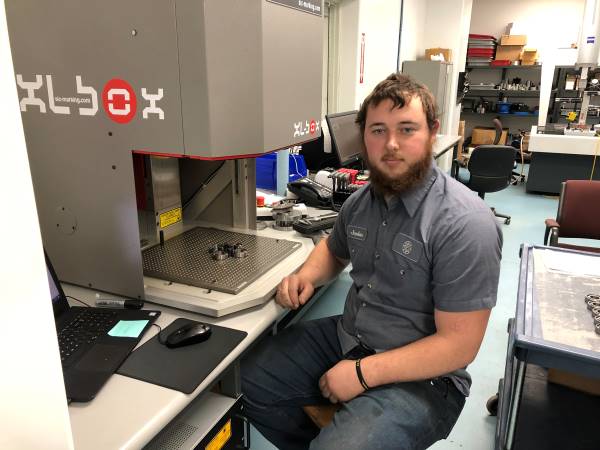

While Lee is set to embark on his new career path, Jordan VanGorder has already begun. A graduate of the machining/CNC operator program, he started as an assembler at Olean’s Napoleon Engineering Services in early January.

While completing the 480-hour training in Cattaraugus County, VanGorder connected with Napoleon during a mock interview and career fair at the end of the program that helps students network with local manufacturers.

Like Lee, VanGorder is happy in his new line of work.

“It definitely changed my life for the better,” he said. “From my previous job, I got a pretty large raise in income. The atmosphere at my job is way more positive than my last job. Everybody seems happier.”

VanGorder previously worked as a polisher. After leaving that job, he visited a Pennsylvania CareerLink office closest to his home in Smethport, Pa.

“They steered me in the direction of going to school,” he said. “JCC was one of those options, and I wanted to be a CNC machinist. When I graduated high school I said I would never go to college. And then this opportunity arose, and I couldn’t turn it down.”

Chad Burdette was less sure about joining the maintenance technician training when a co-worker mentioned it. At the same time, he was growing tired of the repetitive tasks of factory production work he was accustomed to as a boring operator and toll grinder.

“I said, hey, I don’t have much to lose really. This job isn’t going anywhere anytime soon,” Burdette said. “It sounded like a field I would enjoy more, working with my hands on something different everyday.”

Burdette said he was recently hired by Jamestown Electroplating for a maintenance technician role that calls on him to perform a variety of tasks, including electrical wiring, checking fuses, and troubleshooting.

The Youngsville, Pa. resident is happy with his new job, plus the opportunity to advance and make more money.

Burdette said benefits of the JCC program include flexible class times, small instructional settings, and hands-on training from instructors with industry experience

“If someone is looking for a change or even a step in the right direction to something else or something they would enjoy more,” he said, “it’s definitely the way to go.”

Burdette has stayed in touch with Lee and others in the class through an online group chat. They often talk about employment offers, work experiences, and what’s next.

Most have started or accepted jobs while others have opted to continue their education through credit courses at JCC. They are only getting started.

VanGorder, for one, would like to team with his brother, a certified gunsmith, to open a business that uses his new-found CNC skills to produce better quality firearms at faster rates.

The rejuvenated Lee, meanwhile, has aspirations of working in robotics and programmable logic controller (PLC) programming, which he got a taste of during his JCC training.

“That ,” he said, “was the most fun I had the entire class. It’s stuff that most people don’t get to learn. Especially for free.”

The programs are made possible through funding provided by a grant from Empire State Development and the Ralph C. Wilson, Jr. Foundation administered by the Community Foundation for Greater Buffalo.

For more information and how to enroll, visit sunyjcc.edu/cnc-mt